In an era where precision and efficiency are paramount in both industrial and research settings, the advent of high-powered laser technology has transformed various fields immensely. Among the plethora of laser options available, the 500 watt laser stands out due to its remarkable capabilities and diverse applications. In this article, we will explore the advantages, applications, and future potential of 500 watt lasers, emphasizing why they are becoming indispensable tools in many sectors.

Understanding 500 Watt Lasers

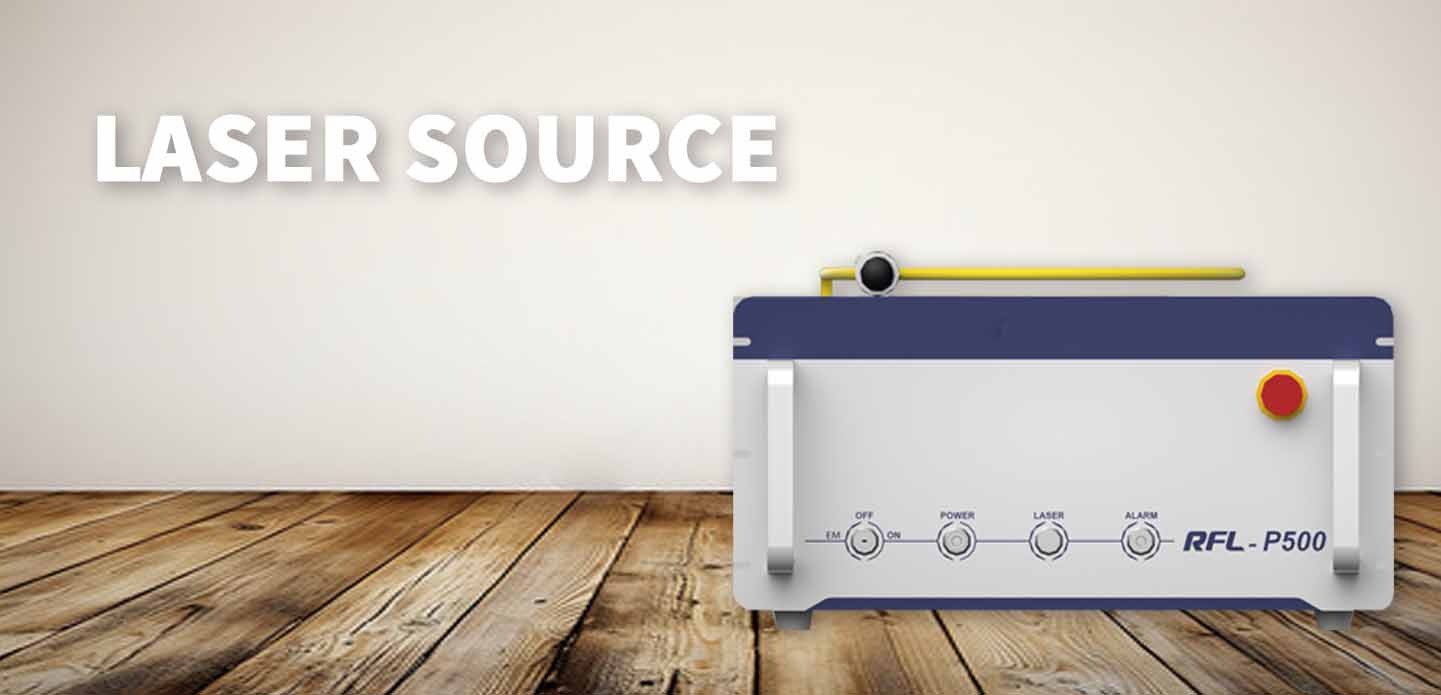

A 500 watt laser emits a concentrated beam of light that can be used for cutting, welding, engraving, and other processes that require high levels of accuracy. The term “watt” refers to a unit of power; hence, a 500 watt laser can deliver significant energy to the material it interacts with. The high power output allows for faster processing times, improved quality of cuts and welds, and the ability to work with thicker materials compared to lower wattage lasers.

Advantages of 500 Watt Lasers

1. **Higher Efficiency**: One of the primary benefits of a 500 watt laser is its efficiency. With its ability to cut through tougher materials like metals and plastics quickly, industries can produce more parts in less time, resulting in enhanced productivity.

2. **Versatility in Material Processing**: 500 watt lasers can process a wide variety of materials, including stainless steel, aluminum, wood, and various plastics. This versatility makes them suitable for different sectors, from manufacturing to research.

3. **Precision and Quality**: The focused beam of a laser ensures that cuts are clean and precise, reducing the need for secondary processes such as finishing or sanding. This precision is crucial in industries like aerospace and medical device manufacturing, where tolerances are extremely tight.

4. **Reduced Waste**: Laser cutting is known for its minimal kerf width, which means there is less material waste compared to traditional cutting methods. This is not only cost-effective but also environmentally friendly, as it contributes to a reduction in scrap material.

5. **Automation and Integration**: Many modern laser systems, including 500 watt models, can be easily integrated into automated production lines. This capability allows for continuous operation and minimal human intervention, which can help reduce labor costs and human error.

Applications of 500 Watt Lasers

1. **Manufacturing**: In manufacturing settings, 500 watt lasers are widely used for cutting and welding metals. Automakers, for instance, use high-powered lasers to assemble parts with precision, ensuring high structural integrity and reliability.

2. **Signage and Engraving**: The engraving industry benefits from the capabilities of 500 watt lasers to create intricate designs on a variety of materials. From personal gifts to commercial signage, the versatility and detail achievable with this technology are unparalleled.

3. **Aerospace and Defense**: The aerospace sector relies heavily on high-precision tools, making 500 watt lasers ideal for the fabrication of parts that require exacting standards. Laser welding is often employed in assembling critical components, ensuring safety and durability.

4. **Research and Development**: In laboratories, 500 watt lasers are used for experimental purposes, including material analysis, experimentation with new materials, and in processes such as laser-induced breakdown spectroscopy (LIBS). This application enables researchers to gain insights into material compositions effectively.

5. **Medical Device Manufacturing**: The medical industry demands high precision in the manufacturing of devices and equipment. 500 watt lasers are employed to cut and shape devices with exact specifications, ensuring that they meet the stringent regulations and standards of healthcare.

Conclusion

The 500 watt laser presents a powerful tool in today’s industrial and research environment, offering an array of advantages that enhance productivity, precision, and efficiency. As technology continues to evolve, the applications and potential of these high-powered lasers will likely expand, paving the way for new innovations and processes that were previously unimaginable. With the persistent demand for accuracy and quality in various sectors, it is clear that 500 watt lasers will play a crucial role in shaping the future of manufacturing, research, and many other industries where excellence is standard.

由投用户稿件整理稿件发布,不代表本站观点及观点,更多交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。