Comparison of Laser Marking Control System Features

| Ezcad2 Laser Marking Control System | Ezcad3 Laser Marking Control System | |

| Software | EZCAD2 | EZCAD3 |

| Hardware | LMC Series Control Card | DLC Series Control Card |

| Connection Method | USB/PCIE | USB/PCIE/Ethernet |

| Axis Control | 2-Axis | 4-Axis/6-Axis |

| TCP/IP Variable Text Transmission | √ | √ Supports Remote Command Control |

| REMARK | √ | √ Supports Big Data Offline |

| High-Precision Scanner Calibration | √ | √ |

| Multi-file Processing | √ | √ |

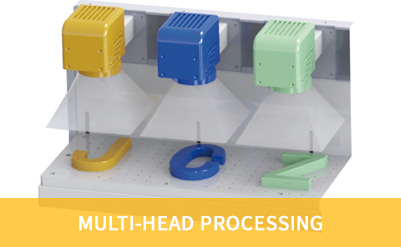

| Multi-head Support | √ 8 – Galvo | √ 32 – Galvo |

| Flying Marking | √ | √ 2-Axis flying |

| Camera Imaging | √ | √ |

| Secondary Development | √ | √ |

| Dynamic Focus | × | √ |

| 2.5D | × | √ |

| 3D | × | √ |

| Constant-Speed Marking | × | √ |

| Fast QR Code Marking | × | √ |

| Linear Changes in Power, Speed, Frequency | × | √ |

| Circular Arc Processing Enablement | × | √ |

| Fill Optimization | × | √ |

| Galvo Status Feedback | × | √ |

| Prevent the Growth of Light | × | √ |

| Double – galvo Control | × | √ |

| Online Firmware Update | × | √ |

| Galvo Protocol | XY2 – 100 | XY2 – 100, SL2 – 100 – 20, JCZ – 100 – 24, CANON – 64, RAYLASE – XY2 – 100 |

| Laser Types | FIBER, CO2, UV, YAG, SPI | Supports Various Mainstream Laser Types |

Ezcad2 Laser Marking Control System

Applied to general laser processing equipment.

Typical Applications

EZCAD3 Laser Marking Control System

Applied to high-precision micro/nano processing and high-power welding and cutting equipment.

Typical Applications

| Configurations | Details |

| Software Kernel | 32 Bit |

| Laser | Supports CO2, YAG, FIBER, SPI, etc., and can adjust current, pulse frequency, duty cycle, and other parameters based on different laser parameters through software |

| Red Light Display | Supports red light as an indicator |

| Password Control | Supports password protection to prevent unauthorized parameter changes |

| IO Control | Added port control functionality for easy automation of your machine |

| Galvo Calibration | Traditional trapezoidal correction, barrel (pillow) correction, and parallelogram correction with dedicated calibration software to achieve extremely precise calibration results |

| Fill | Circular fill, arbitrary angle fill, cross fill, adjustable margins, borders, and spacing, supports 3 layers of filling, with independent parameter settings for each layer |

| Editing Functions | Arbitrary curve text, arbitrary graphic drawing/editing, scatter/combine, group/ungroup, undo/redo, welding, trimming, cross, alignment, automatic curve connection, etc. |

| Text Input Function | Supports TrueType fonts, single-line fonts (JSF), dot matrix fonts (DMF), SHX, and user-created font libraries |

| 256 Layer Processing Parameters | Highly customizable for easy multi-parameter marking |

| Barcodes and QR Codes | Code39, EAN, PDF417, DATAMATRIX, QR, DATAMATRIX-GS1 etc. |

| Vector Files | PLT, DXF, Al, DST, SVG, GBR, NC, JPC, BOT |

| Bitmap Files | BMP, JPG, JPEG, GIF, TGA, PNG, TIF, TIFF |

| Variable Text | Fixed text, date, time, keyboard input, skipping numbers, list files, dynamic files, supports Excel sheets, TXT files, serial communication, and network communication |

| Multi-Language Support | Built-in Chinese, English, Korean, Japanese, French, German; can be easily localized by language packs for translation |

| Optional Features | Dual-axis splicing, flying marking, software secondary development |

| Configurations | |

| Software Kernel | 64 Bit |

| Laser | Supports CO2, YAG, FIBER, SPI, QCW, CW, etc. Can adjust current, pulse frequency, duty cycle, and other parameters through software. Real-time laser status display. Supports JCZ laser digital communication protocol 1.0, compatible with most lasers in the market. |

| Red Light Display | Supports red light as an indicator |

| Password Control | Supports password protection to prevent unauthorized parameter changes |

| IO Control | Added port control functionality for easy automation of your machine |

| Galvo Calibration | 3D calibration, traditional trapezoidal correction, barrel (pillow) correction, and parallelogram correction. Specialized software for precise calibration results. |

| Fill | Background fill, circular fill, arbitrary angle fill, cross fill, adjustable margins, borders, and spacing. Supports 8 layers of filling with independent parameter settings for each layer. |

| Editing Functions | Multi-layer, 3D curve marking, slicing, dynamic filling, 3D curve projection, surface wrapping, bitmap to embossing, arbitrary curve text, arbitrary graphic drawing/editing, scatter/combine, group/ungroup, undo/redo, welding, trimming, cross, alignment, automatic curve connection, etc. |

| Text Input Function | Supports TrueType fonts, single-line fonts (JSF), dot matrix fonts (DMF), SHX, and user-created font libraries |

| 256 Layer Processing Parameters | Highly customizable for easy multi-parameter marking |

| Barcodes and QR Codes | Code39, EAN, PDF417, DATAMATRIX, QR, PostNet, PL ANET, UK Royal Mail 4 state customer, AZTECCODE, MicroQRCODE, VERICODE, etc. |

| Vector Files | PLT, DXF, Al, DST, SVG, GBR, NC, JPC, BOT |

| Bitmap Files | BMP, JPG, JPEG, GIF, TGA, PNG, TIF, TIFF. Supports segmented processing. |

| Variable Text | Fixed text, date, time, keyboard input, skipping numbers, list files, dynamic files. Supports Excel sheets, TXT files, serial communication, and network communication. |

| Multi-Language Support | Built-in Chinese, English, Korean, Japanese, French, German. Easily localized by language packs for translation. |

| Optional Features | Four-axis point-to-point motion, dual-axis splicing, flying marking, software secondary development |

| Calibration Table | Supports loading and switching between up to 4 calibration tables simultaneously |

| Multi-Layer XY Plane Calibration | Improves XY plane calibration accuracy of 3D calibration |

| Offline Mark | Supports switching and processing of up to 16 offline layers |

| Online Circular Arc Interpolation Commands | Supports high-precision small circle processing |

| Three-Dimensional Model Files | STL, DXF |

| Processing Functions | Large-format dynamic focusing, projector positioning, multi-axis expansion, estimated processing time, ultra-fast point-like 2D barcode marking, uniform fill function, gradual power and speed control, circular and sine curve jitter, material parameter assistant function |

| Operation System | Windows 32/64 Bits | Windows 64 Bits |

| Programming Platform | X86 | X64 |

| Programming Language | C#, C++ | |

| Custom API | √ OPTIONAL | |

| Multi Head Library | √ OPTIONAL | √ |

| High Precision Calibration Library | × | √ OPTIONAL |

| Demo Code | √ | √ |

| User Manual | √ | √ |

| Note: EZCAD SDK can only be used with controller directly purchased from JCZ. Ezcad2 SDK only support LMC V4 Standard board (lite board not support) | ||

Laser Inkjet Coding Control System Feature

| J2000 | Mini-FB/SZ-02 | |

| EZCAD2 | × | √ |

| EZCAD3 | × | × |

| Static | √ | √ |

| Flying | √ | √ |

| Trigger Mode | √ | √ |

| Pipeline Mode | √ | √ |

| Three-Phase | √ | √ |

| Text | √ | √ |

| Secondary Development | √ | √ |

| Remote Upgrade | √ | √ |

| Fast Calibration | √ | √ |

| Vector Graphic | √ | √ |

| QR Code | √ | √ |

| TCP/IP | √ | × |

| Serial Communication | √ | × |

| Trigger Delay | √ | × |

| Trigger Shielding | √ | × |

| Screensaver | √ | × |

| Power Failure Protection | √ | × |

| Alarm Light | √ | × |

| Quick QR Code | √ | × |

| Axis Movement | × | × |

| Bitmap | × | √ |

Laser Inkjet Coding Control System Performance Overview

| Performance | J2000 | Mini-FB/SZ-02 |

| System | Linux | Windows 10 |

| Memory | 1GB | 2.00GB |

| Storage | 8GB | 32GB |

| Monitor Size | 10.1 inches | 10.1 inches |

| Maximum Resolution | 1280 * 800 | 1280 * 800 |

| Monitor Type | Resistive Screen | Capacitive Screen |

| Power Supply | 12-24V/2A | 12V/5A |

| Ethernet Port | 1 | 1 |

| Serial Port | RS232 * 1 | 1 |

| USB | 1 | 3 |

| IO | Input 2 Output 3 | Input 5 Output 9 / Input 4 Output 9 |

| Fiber/Digit Laser | Compatible | Distinguish |

System Overview

The J2000, and Mini series laser inkjet coding control systems feature full-coverage metal casings, strong interference resistance, a simple and user-friendly interface, and abundant functionality. This series can be widely used in various industries such as food and beverage packaging, tobacco, alcohol, dairy products, pharmaceuticals, cables, pipes, electronics, and more, for marking graphics and text including production dates, batch numbers, shifts, manufacturer names, and logos.

Typical Applications

System Overview

The laser cutting system is an independently developed control system by JCZ for fiber laser cutting. It features excellent motion control algorithms and process handling capabilities. This system is user-friendly, feature-abundant, stable, reliable, and offers strong performance. It can provide customers with comprehensive laser processing solutions and is widely used in industries such as advertising production, automotive manufacturing, 3C electronics, medical devices, and more.

| Maximum Operating Acceleration | 2 G | Maximum Operating Speed | 150 m/min |

| Positioning Accuracy | 0.001 mm | Repeated Positioning Accuracy | 0.003 mm |

| Special Output | 2 DA | Special input | 8 limitation switch/4 starting point |

| Output | 20 | Input | 16 |

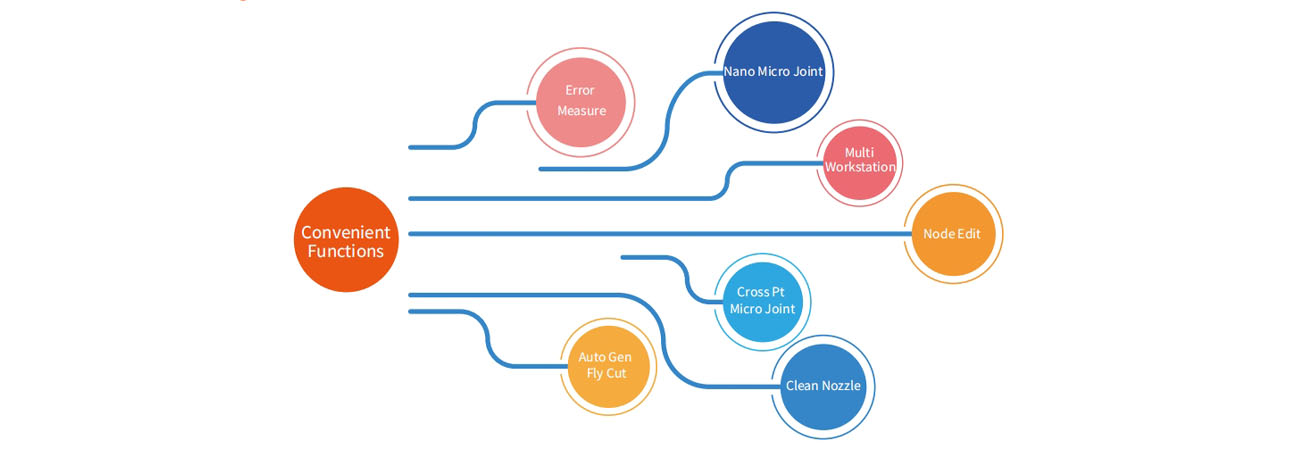

System Advantages

System Architecture

System Architecture

Application Cases

3C Electronics

Laser cutting is used for precision cutting or micro-hole processing of small components, whether they are made of metal or non-metal materials. It offers advantages such as high cutting precision, fast speed, and minimal heat impact. JCZ laser cutting system, with its multi-station and PLC capabilities, finds wide applications in the cutting of electronic products like mobile phones, laptops, and cameras. Its key advantages include precise processing dimensions, clear contours, especially for the precision machining of various high-end materials with high hardness, high brittleness, and high melting points. This effectively enhances the quality of processing, and compared to traditional tool cutting, contactless cutting improves the product yield.

Glass Cutting

Cutting brittle materials like glass, representing a new application in the field of laser processing, is made possible with the use of ultra-fast lasers and JCZ laser cutting system with PSO functionality (500mm/s speed with arc accuracy of ±0.2um between points). This combination allows for high-speed and high-precision cutting of glass. When combined with post-cutting processes, it results in high-quality glass products with precise shapes.Cutting brittle materials like glass, representing a new application in the field of laser processing, is made possible with the use of ultra-fast lasers and JCZ laser cutting system with PSO functionality (500mm/s speed with arc accuracy of ±0.2um between points). This combination allows for high-speed and high-precision cutting of glass. When combined with post-cutting processes, it results in high-quality glass products with precise shapes.

Typical Applications

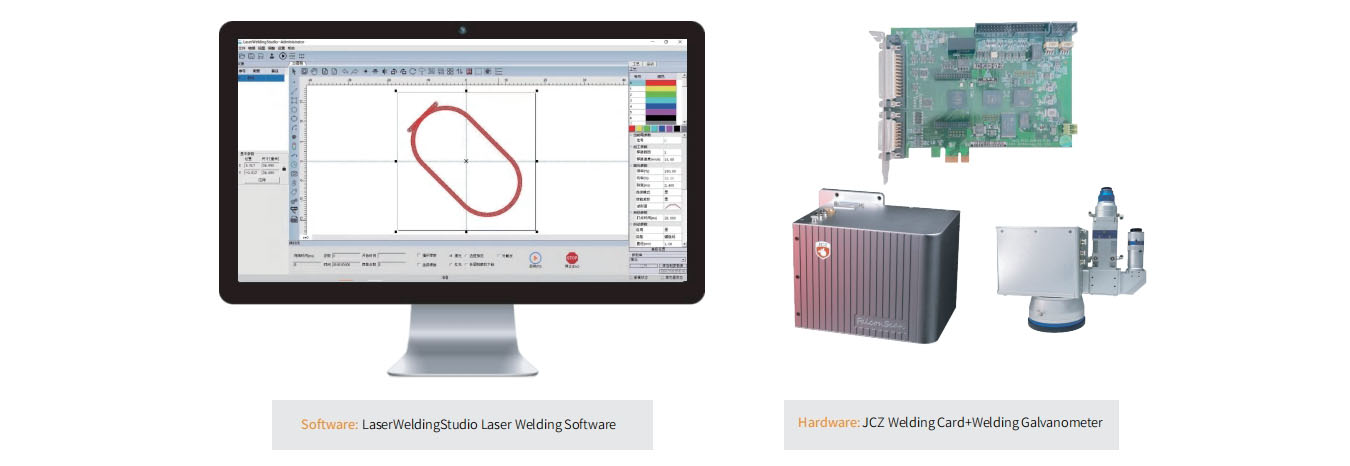

System Overview

JCZ’s independently developed galvanometer welding system is suitable for medium and high-power welding applications. This system supports dual-beam control for circular laser beams, allowing for real-time position feedback and monitoring of the galvanometers. It ensures system security and reliability through features like access control and production modes. Additionally, the system integrates multiple-axis motion control and machine vision positioning functions, covering the requirements of multi-station, high-precision applications. It is characterized by high execution efficiency, excellent welding quality, strong adaptability, and ease of automation integration. It can be widely used in industries such as lithium batteries, photovoltaics, and 3C electronics.

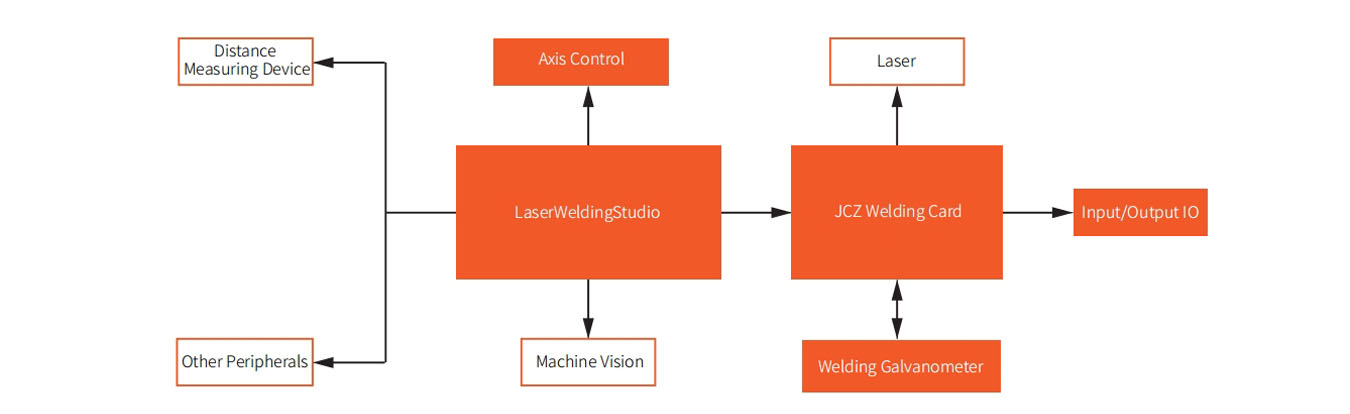

System Architecture

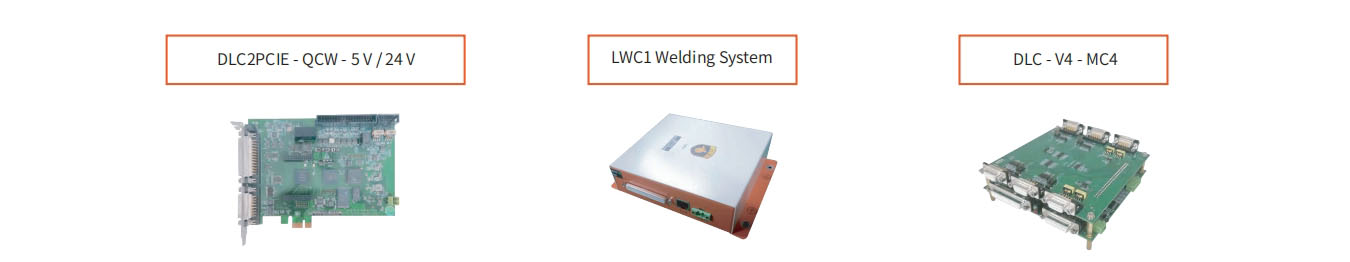

Welding Control Card

| Hardware Description | DLC2PCIE – QCW – 5V/24 V | LWC1 Welding System | DLC – V4 – MC4 |

| Upper Computer | PCIE | Ethernet | Ethernet |

| Communication Interface | 10 Input, 8 Output | 16 Input, 16 Output | 10 Input, 8 Output |

| Laser Interface | QCW5 V/24V | QCW 24 V | Multiple Laser Types |

Welding Scanner

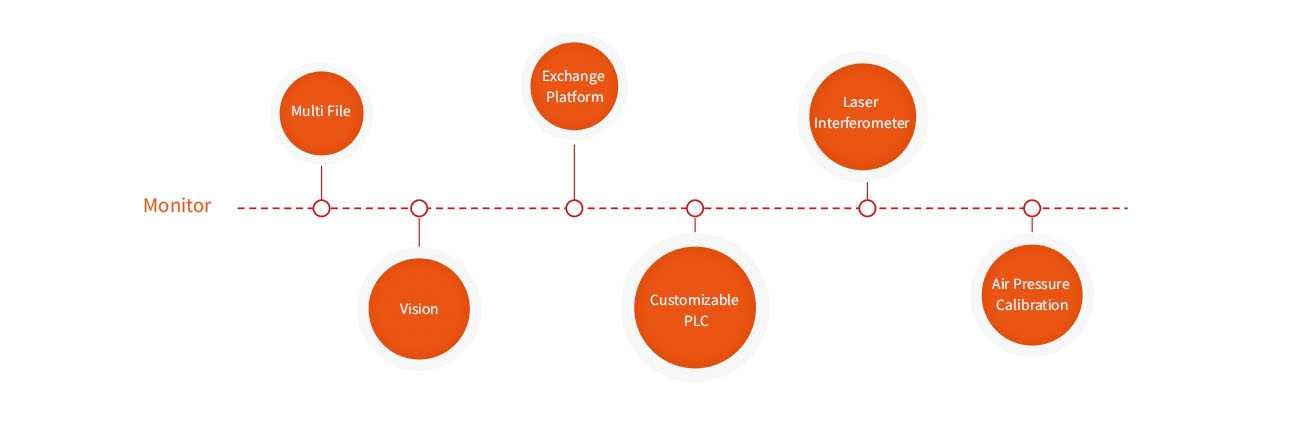

System Functions

Graphic processing Supports point, line, arc, spiral, rectangle, and arbitrary curve drawing, as well as DXF import

Teaching Allows mouse movement to offset galvanometer position, with welding location determined through coaxial vision

Multiple Graphics Files Enables combination processing of multiple graphics files and logic control through various triggering methods

Jitter Control Supports sine, spiral, figure-eight, and inverted figure-eight patterns, with adjustable density and speed of jitter trajectories

Linear Power Transformation Supports setting the length and ratio of the start and end to achieve gradual power increase and decrease

Power Curve Allows editing of the time-power curve to meet complex process scenario requirements

Dual Analog Control Editable analog waveform charts for center and ring light, enabling control of dual-beam laser

IO Includes input waiting and output control, providing flexible operation for task flow control

Motion Control Supports up to 4-axis stepper or servo motor drive control for various forms of automated welding integration

Machine Vision Customizable vision positioning assistance system to meet changing scenario requirements

Offline Mode Supports up to 8 offline files triggered through input pins

System Features

High Efficiency Supports multiple graphics files, multiple workstations, automatic optimization of multi-segment welding trajectory processing order, and galvanometer jump optimization.

Your Content Goes Here

Your Content Goes Here

Your Content Goes Here

Your Content Goes Here

Your Content Goes Here

Your Content Goes Here

Your Content Goes Here

Your Content Goes Here

Your Content Goes Here

Your Content Goes Here

Your Content Goes Here