In today’s fast-paced industrial landscape, the quest for efficiency and precision in manufacturing processes has been a pivotal focus for engineers and designers alike. A groundbreaking innovation that has recently garnered attention is the hand-held metal laser. This technology not only streamlines various metal processing tasks but also improves accuracy and versatility, making it an indispensable tool in various fields, including construction, automotive, aerospace, and artwork creation. This article delves into the features, applications, advantages, and future of hand-held metal lasers in modern manufacturing.

What is a Hand Held Metal Laser?

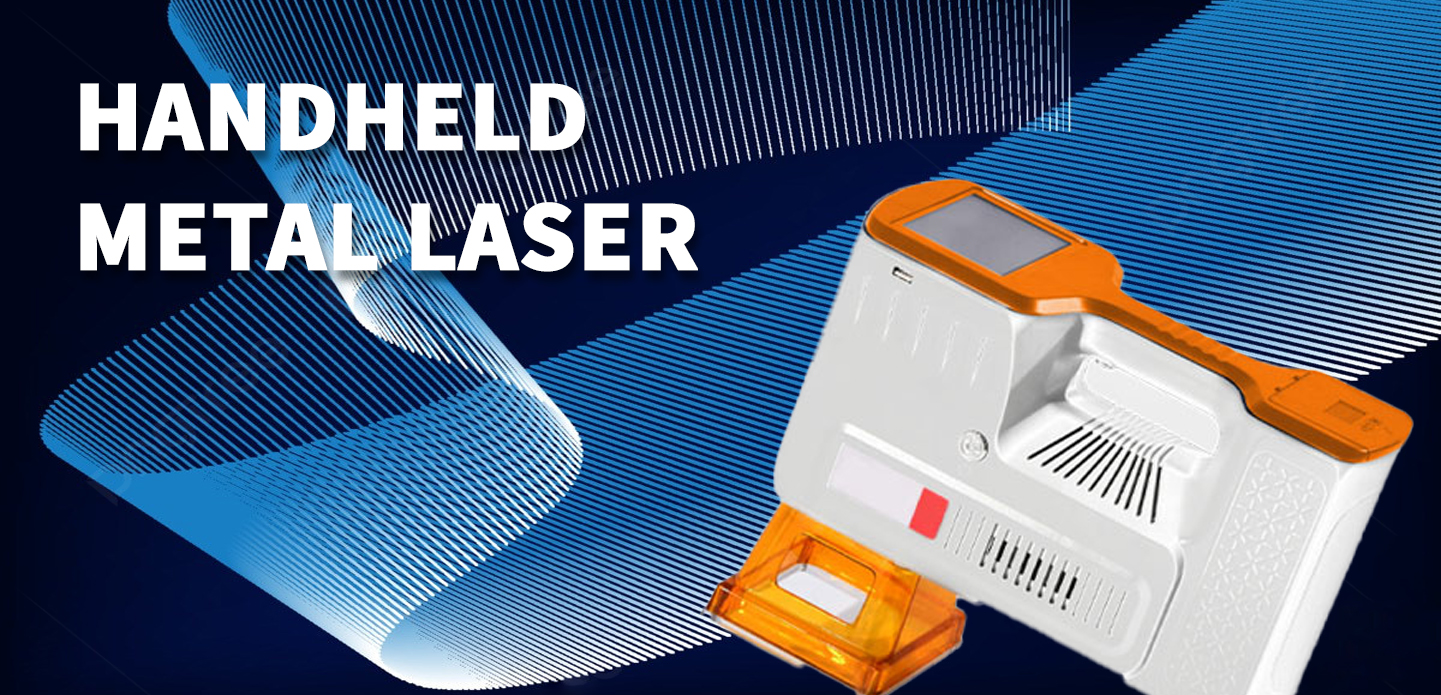

Hand-held metal lasers are advanced cutting and welding tools that utilize laser technology to precisely cut or join metal materials. Unlike traditional welding and cutting methods, which often require cumbersome equipment and setups, hand-held lasers provide the mobility and flexibility needed for a wide range of applications. These devices typically consist of a laser source, lens, and a handheld control mechanism, allowing operators to maneuver the laser with ease while maintaining a steady beam.

Applications in Various Industries

The adaptability of hand-held metal lasers lends itself to multiple applications across diverse industries.

1. Manufacturing and Fabrication: In metal fabrication shops, these lasers are used for precision cutting, edge finishing, and engraving. The high energy concentrated in the laser beam allows for clean, burr-free cuts, reducing the need for additional finishing processes.

2. Construction and Repair: Hand-held metal lasers are invaluable in construction applications where precise cuts are needed on-site. They are particularly useful for cutting structural steel or pipes and can adeptly handle various thicknesses, making repairs and modifications seamless.

3. Automotive Industry: The automotive sector frequently employs hand-held metal lasers for welding components together, particularly with the rise of lightweight materials. These lasers offer the ability to make quick, strong welds that are crucial for vehicle safety.

4. Aerospace: The aerospace industry requires extreme precision and adherence to strict regulations. Hand-held lasers are used to repair components quickly and accurately, minimizing downtime and ensuring that high safety standards are maintained.

5. Art and Design: In the world of art, designers and creators are increasingly turning to hand-held lasers for intricate metalwork. The ability to cut and engrave complex designs on metal surfaces has opened new avenues for artistic expression.

Advantages of Hand Held Metal Lasers

The benefits of using hand-held metal lasers over traditional methodologies are significant:

– Precision: The concentrated nature of laser beams provides exceptional accuracy, allowing for tight tolerances and intricate patterns that are challenging to achieve with other tools.

– Reduced Waste: The precision cutting technology minimizes material waste, which is advantageous for both cost-saving and environmental considerations.

– Versatility: These lasers can work on various metal alloys and configurations, from thin sheets to thicker materials, providing a versatile tool for diverse applications.

– Portability: Being hand-held, these tools are highly portable, making them ideal for job sites where mobility is essential. Operators can easily transport them to different locations, making on-the-spot work efficient and effective.

– Time Efficiency: The speed at which hand-held lasers operate reduces the time spent on tasks, significantly increasing overall productivity in manufacturing and repair jobs.

The Future of Hand Held Metal Lasers

Looking ahead, the future of hand-held metal lasers appears bright. With advancements in laser technology, there are opportunities for even greater efficiency, improved battery life for cordless operation, and enhanced user interfaces that integrate with smart technologies.

Additionally, as industries increasingly focus on sustainability, the shifts toward energy-efficient and low-waste manufacturing will likely drive further adoption of these innovative tools. Training programs may evolve to include the use of hand-held lasers, ensuring that the next generation of engineers and technicians is equipped to leverage this technology effectively.

In conclusion, hand-held metal lasers represent a significant advancement in the realm of metal processing and manufacturing. Their versatility, precision, and efficiency make them an essential asset across various industries, and as technology progresses, they will undoubtedly play a crucial role in shaping the future of manufacturing practices. As more professionals embrace this innovative tool, the possibilities for what can be achieved are virtually limitless.

由用户投稿整理稿件发布,不代表本站观点及立场,仅供交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。