When we take it for granted that laser marking machines are merely used to engrave various production codes onto products, laser technology has already achieved in-depth advancements in its applications.

Through continuous integration and adaptation, innovation has been steadily emerging.

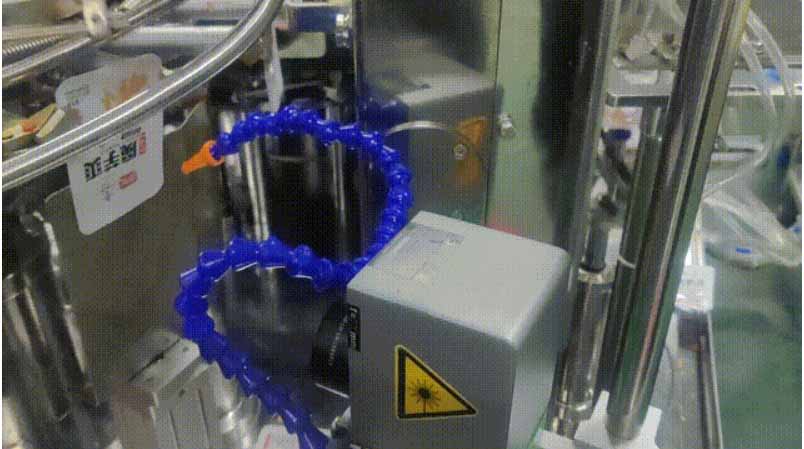

From the simple setup of “placing the laser equipment beside the production line” to making seemingly small but practically significant design innovations to accommodate various packaging machinery (such as multi-row packaging machines, injection molding machines, and paging machines), laser marking is now heading towards diversification and customization.

For example, to adapt to different marking surfaces, directions, and heights, certain automated series have adopted a rotatable laser marking head design. The head can rotate 360°, allowing the equipment to maintain production line flexibility without significant movement of the machine body or its support, thus greatly reducing installation and operation complexity.

Similarly, handheld marking series have thoughtfully incorporated options such as exhaust fans, distance sensors, and magnetic spacers for users to choose from.

Taking the exhaust fan as an example, some users’ operating environments or marking materials may generate smoke and dust. If not cleaned over time, this could shorten the lifespan of the focusing lens. The small exhaust fan helps prevent dust from accumulating inside the focusing cover to a certain extent.

In the upstream production of large-scale industrial packaging, application equipment that integrates sorting, feeding, loading, marking, inspection, rejection, collection, and traceability based on laser machines has garnered attention.

The paging marking all-in-one machine, for instance, is designed for various unformed packaging boxes and bags. It rapidly marks secondary and tertiary codes, includes a vision detection and rejection system, and features precise recognition of missing markings and QR code reading capabilities.

Meanwhile, the cap sorting and marking machine targets cap manufacturers, including commonly used 28mm and 38mm caps. It not only ensures precise rejection with a rejection device but also features a code issuance system to perform historical data comparisons, guaranteeing the uniqueness of QR codes and barcodes.

When paired with ultraviolet laser marking equipment, high-efficiency marking of QR codes, dates, and numeric codes is achieved. The combination of low-heat processing technology and fine laser beams is suitable for both inner and outer caps, ensuring that laser marking does not produce pollution or toxic chemicals, thereby protecting the safety of the bottled contents.

There are even more distinctive laser applications awaiting feedback and demand from users, inspiring further technological improvements and innovations.

Company Introduction

Beijing JCZ Technology Co., Ltd. (Stock Code: 688291) was established in 2004 and focuses on the research and development of control software, systems, and components in the field of laser industrial processing. It is recognized by the Ministry of Industry and Information Technology as a specialized and innovative “The Rising Star Award” enterprise, a specialized and innovative “The Rising Star Award” enterprise in Beijing, a high-tech enterprise recognized by the Beijing Municipal Science and Technology Commission, and a partner unit in Fengtai District’s “Doubling Catch-up and Cooperative Development” initiative.

In the future, JCZ will continue to innovate technologically and strive to build a “Beam Delivery & Control” technology platform, providing customers with “Integrated Drive and Control” products and comprehensive solutions, delivering high-quality products and services to system integrators and users, and becoming a competitive and influential “Beam Delivery & Control Expert.”