| Configurations | ||||

| Scanner | Input Diameter | 10 mm | ||

| Tracking Error | 0.25 ms | |||

| Marking Speed | 4000 mm/s | |||

| Positioning Speed | 10000 mm/s | |||

| 1% Full Scale | ≤ 0.4 ms | |||

| Repeatability | < 8 μrad | |||

| Gain Drift | < 50 ppm/K | |||

| Offset Drift | < 15 μrad/K | |||

| Drift Over 8h | < 0.3 mrad | |||

| Nonlinearity | < 3.5 mrad/44° | |||

| Interface | XY2 – 100 | |||

| Scan Angle | ± 0.35 rad | |||

| Optical | Wavelength | 1064 nm | 532 nm | 355 nm |

| Dynamic Zoom System Parameters | Input Aperture | 7 mm | 7 mm | 3 mm |

| Beam Ratio | 1.4 | 1.4 | 3 | |

| Marking Area | ± 30 mm (F254-174lens) | ±7 mm (F165-115 lens) | ± 15 mm (F254-175lens) | |

| Focus Range | 1500 (Replaceable F-θ lens) | 100 (Replaceable F-θ lens) | 150 (Replaceable F-θ lens) | |

| Basic | Power | ± 15 V DC, 5 A | ||

| Working Temp | 25 ± 10°C | |||

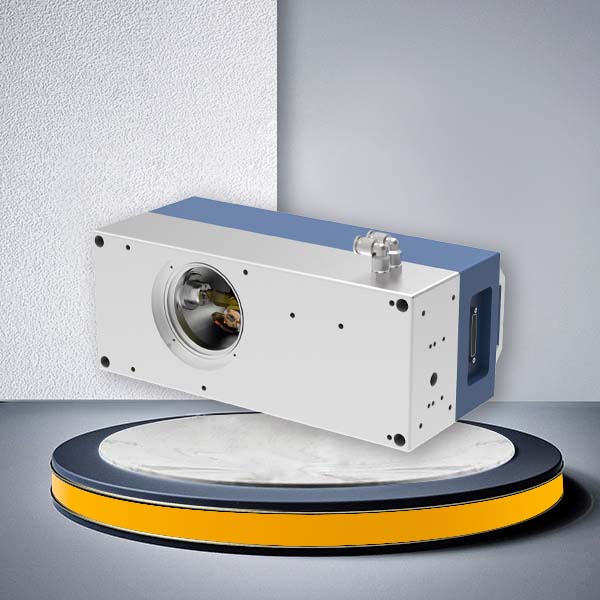

G3 3D adopts the third axis module developed by JCZ, which has faster response speed, faster zoom and more stable. The system has strong anti-interference ability, high reliability, good linearity, high repetition precision and short response time. The system adopts integral structure with small volume, light weight and good sealing performance to ensure the stability under long working conditions. G3 3D is suitable for complex curved surface processing, 3D deep carving, high power cutting, drilling, laser micro processing, 3D printing, etc. According to the different wavelength and mirror size, it can process various materials such as metal, leather, rubber, wood, bamboo products, ceramic tile, plastic, marble, jade and other materials.