| Configurations | ||

| Parameter | Model | G3 Weld – 30 |

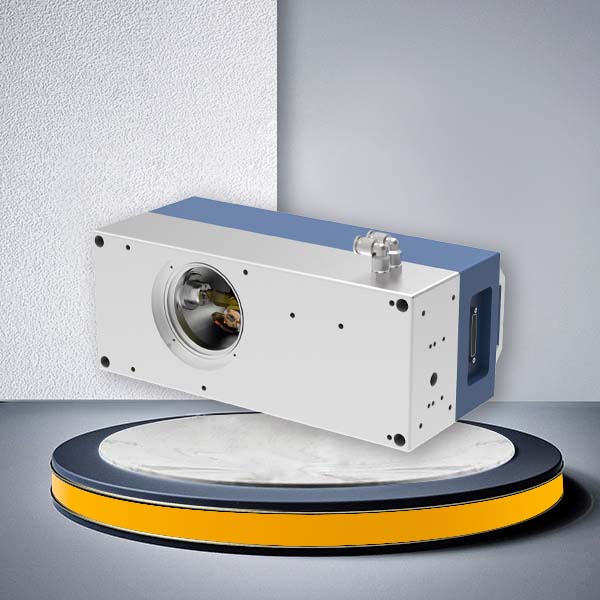

| Scanner | Mirror Aperture | 30 mm |

| Tracking Error | 0.58 ms | |

| Marking Speed | 700 mm/s | |

| Positioning Speed | 3000 mm/s | |

| 1% Full Scale | 1.5 ms | |

| 10% Full Scale | 4.2 ms | |

| Repeatability | < 10 μrad | |

| Gain Drift | < 30 ppm/K | |

| Zero Drift | < 30 μrad/K | |

| Drift Over 8h | < 0.3 mrad | |

| Nonlinearity | < 3.5 mrad/44 ° | |

| Scan Angle | ± 0.35 rad | |

| Signal Wavelength | Interface | XY2 – 100 |

| Power Supply Parameters | Power | ± 15 V DC, 5 A |

| Basic | Working Temp | 25 ± 10 ℃ |

| Cooling Method | Water Cooling | |

Laser welding can be applied to a variety of metals and their alloys, including titanium, nickel, tin, zinc, copper, aluminum, chromium, niobium, gold, and silver, as well as alloys like steel and cobalt alloys. It can also be used for welding similar materials such as steel and cobalt alloys, as well as dissimilar metals like copper-nickel, nickel-titanium, copper-titanium, brass-copper, and low-carbon steel-copper. Laser welding is suitable for high-power welding applications in industries such as electronic components, automotive parts, and precision instruments.